-

POCKET BOX TARGETS ROAD TRANSPORT SECTOR WITH ASSET MANAGEMENT ENHANCEMENT - 16 hours ago

-

PINPOINTERS ENHANCES FLEET AND VIDEO TELEMATICS OFFERING WITH LINK-UP WITH QUECLINK WIRELESS SOLUTIONS - 2 days ago

-

BCMPA HELPS TO OPEN DOORS FOR US TRADE PARTNERSHIPS - 2 days ago

-

Toyota’s ride-on stacker and delivery drone win prestigious design awards - April 23, 2024

-

ARROWXL SECURES FIFTH CONSECUTIVE GOLD ROSPA AWARD - April 19, 2024

-

Delivery management platform, Scurri topped over €12 billion in Gross Merchandise Value (GMV) in the total value of shipments processed in 2023 - April 17, 2024

-

Britvic reaffirms partnership with LPR - April 17, 2024

-

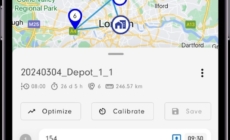

Geo2 routes for the planet by transforming delivery - April 9, 2024

-

Kammac Supports Nimble’s Expansion into 500 Tesco Stores - April 5, 2024

-

Axiom Sustainability Software launches groundbreaking Social Value Calculator - April 4, 2024

Huge interest at ProMat as Pineberry launch new products for packaging automation.

Pineberry Manufacturing Inc. recently exhibited at MHI’s ProMat Show debuting new innovation, InstaPrint Packing Slip Inserter and innovation of an existing product, Open Source Friction Feeder. Demonstrating the latest innovations in material handling, e-commerce fulfilment and packaging automation, the Pineberry team met with hundreds of international ProMat Show and Automate attendees and OEMs. Pineberry Manufacturing Inc. walked away from ProMat Show with many new high quality business leads, making this one unforgettable and successful industry trade show.

“The Pineberry team was overwhelmed by the amount of interest ProMat Show and Automate attendees had on our InstaPrint Packing Slip Inserter and our Open Source Friction Feeder,” states David McCharles, President of Pineberry Manufacturing Inc. “Our InstaPrint Packing Slip Inserter prints, scans and inserts up to 200 pages per minute on demand, greatly reducing bottlenecks, labor costs and improving automated packing slip order fulfillment. In addition, InstaPrint folds packing slips for quick insertion into small boxes and cartons,” continues Mr. McCharles. “InstaPrint Packing Slip Inserter prints packing slips, invoices, marketing collateral, coupons, etc. meeting same-day shipping promises and inserting marketing/promotional collateral to increase repeat orders. With an inkjet drop-on-demand printer and no printer duty cycle, if a rare jam occurs it can be cleared in seconds, unlike a laser printer, making InstaPrint Packing Slip Inserter the most reliable packing slip automated system on the market.”

“Our Open Source Friction Feeders easily integrates into manual and automated packaging lines and comes with a user-friendly touchscreen display,” said Mr. McCharles. Our Open Source Friction Feeders can be integrated with inkjet print heads, bar code scanning, camera verification and inspection, u-board folder, speed matching and batch counting. Simplified, compact and cost effective, the device’s parameters are displayed on a simple photographic terminal that shares real-time machine performance information through an app on a smartphone,” concludes Mr. McCharles.

Pineberry Manufacturing Inc. also provided attendees with great insight into affixing, top serters, collation systems, verification/inspection systems, serialization and track and trace systems, bar code printers and scanners, inkjet printing/labeling, packaging machinery and tray denesting. We discussed the various Pineberry innovations in manufacturing, distribution and supply chain equipment and systems. With Christmas and other holidays quickly approaching later this year, the Pineberry team conversed the importance of order fulfillment automation, same-day shipping, decreasing bottlenecks during peak seasons, and inserting marketing/promotional collateral to increase repeat orders and customer loyalty.

In case you missed us at ProMat Show, we invite you to visit: www.pineberryinc.com