-

ROSSLARE EUROPORT TARGETS HEALTH & SAFETY WITH CAMERA TELEMATICS PARTNERSHIP - 2 days ago

-

Landmark Study Reveals Wearable Robotics Significantly Boost Safety and Efficiency in Industrial Environments - July 24, 2024

-

Visku Tackle The Retail Seasonality Challenge One Pallet At A Time - July 22, 2024

-

KAMMAC AND BERGEN LOGISTICS STRENGTHEN FASHION & LIFESTYLE SERVICES IN THE UK - July 19, 2024

-

TENTBOX EXTENDS PARTNERSHIP WITH ARROWXL TO SUPPORT INCREASING DEMAND - July 17, 2024

-

The Perfume Shop improves customer journeys while driving profitability in partnership with Scurri - July 17, 2024

-

ZEROMISSION SECURES £2.3M ($3M) INVESTMENT TO ACCELERATE ELECTRIC FLEETS - July 16, 2024

-

BCMPA CELEBRATES SUCCESS OF 2024 CONFERENCE - July 15, 2024

-

Best of the Best: Jungheinrich Celebrates Triple International Award Win - July 12, 2024

-

GOPLASTICPALLETS.COM CALLS ON NEW CHANCELLOR RACHEL REEVES TO CONSIDER PLASTIC PACKAGING TAX REFORM - July 10, 2024

Gateway to Supply Chain Sanity.

Data sharing can work if all stakeholders stick to the rules of the game

Every haulier, dispatcher and transport manager in industry and trade knows the problem: if an unforeseen disruption occurs along the supply chain, this information does not necessarily reach everyone involved in the transport process.

The reasons are many but most likely because of incompatibilities of different telematics systems and information tools. Quite simply, they don’t speak the same language.

For some time, this problem has been partially dealt with by so-called transaction platforms which consolidate data streams from proprietary systems so that data from partners in the transport process can be processed immediately. But that doesn’t work in today’s supply chain as many data integrators often do not act independently, but pursue different goals.

GateHouse Logistics pursues a different approach for data transparency in the transport sector. It sells its ghTrack gateway to so-called data subscribers … transport companies and shippers … who want data processes to be transparent and accessible. With data transparency, they can track all shipments via a single portal at any time. The data subscriber can either purchase this service on a per-use basis or as required for the entire fleet. The model does not include a basic fee and for those who only provide their data, no costs are incurred.

“The special feature of the solution is not just that the GateHouse software is able to capture data from around 400 systems and to display them consistently on one screen, but that the portal is strictly neutral in dealing with the information,” says Jesper Bennike, CEO, GateHouse Logistics.

This means that the GateHouse Logistics platform determines who is to be given what data, but has no influence on the content. However, whether data is made available to a partner is determined – and this is the key difference – solely by the transport company as a data supplier itself, although the transport company is not paid for this service.

Aside this, GateHouse Logistics does not record any data concerning transported goods. So how is data management organized?

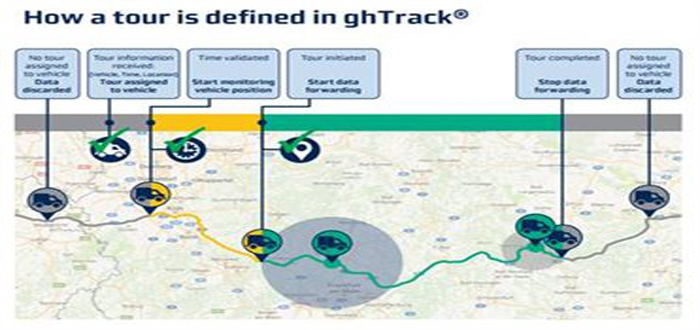

To start data forwarding, tour information (vehicle ID, time and locations) must be supplied to the tour engine in ghTrack. This ensures that the right vehicle is at the right place at the right time – only then the monitoring window is opened and data released towards the right customer.

First and foremost, transport data is generated per tour and is only available until the completion of this tour. The recording of tour data only starts when a vehicle has been assigned an order. This can be up to 24 hours before the actual pickup.

At this point, no transport information is passed to the customer. Data transmission is not opened until the vehicle reaches the 50km radius around the pickup point. The customer will then be informed by the system before the vehicle reaches the target point. The collection ramp can be organised just before the vehicle reaches the pick-up location.

From then onwards, the system works like a normal shipment tracking system: the position of the vehicle is monitored and relevant changes are displayed. As soon as the vehicle approaches the delivery location, a separate alarm is triggered.

As soon as the goods are delivered, data acquisition for the tour is terminated until the truck is assigned a new tour.

The platform has already been adopted by several large logistics service providers in Germany. Four years ago, one decided to display its own fleet on the GateHouse Logistics system as well as the vehicles of tour subcontractors. More than 11,000 vehicles from 300 service providers employing some 250 telematics solutions were integrated.

So, what concrete benefits does the GateHouse Logistics platform provide shippers and transport companies?

In addition to knowing specific information about any transport order, the shipper is primarily interested in organizing and optimizing transport fleets … avoiding empty journeys, smoothly providing the supply of his own plants with raw materials, and improving time window management at ramps to supervise delivery of goods.

For transport companies, it is important to minimize the number of empty miles that fleets run. Since it has exactly the same data as its client, a transport company can balance the billing of its service … a win-win situation for all concerned where none of the parties involved have to accept the disadvantages of empty mileage billing.

Data rights along the supply chain

The legal situation in transferring and distributing telematics data is still unresolved today so many forwarders and transport companies are therefore hesitant to transmit digital information. Gatehouse Logistics is convinced about the advantages of the use of telematics data by all market participants, and the company now promotes a Bill of Rights to prevent the misuse of data.