-

Data-driven maintenance - October 25, 2024

-

Denby Pottery partners with ESW to overcomes post-Brexit issues and launch DTC in 29 European markets - October 24, 2024

-

BLACKOUT TECHNOLOGIES TARGETS SMARTPHONE DISTRACTION BEHIND THE WHEEL TO BOOST FLEET AND DRIVER SAFETY - October 23, 2024

-

NATUREWALL ANNOUNCES NEW PARTNERSHIP WITH ARROWXL - October 23, 2024

-

Trained fork truck operators lift safety standards and lower business costs - October 23, 2024

-

Tower Launches Customer Sustainability Hub with Practical Tools for Lower-Impact Pharmaceutical Cold Chain - October 16, 2024

-

Six decision-making models for best practice WMS digital transformation - October 16, 2024

-

“Transforming Logistics: Precision and Purpose” – BIFA takes centre stage - October 15, 2024

-

JAMES JONES & SONS LTD EXPANDS ITS PALLETS & PACKAGING DIVISION THROUGH THE ACQUISITION OF HG TIMBER LTD - October 10, 2024

-

HUGO BECK EXPANDS MACHINE RANGE FOR E-COMMERCE, MAIL ORDER AND LOGISTICS - October 10, 2024

Low-CapEx technology is leading SME’s to look at flexible and scalable, warehouse automation as a means to overcoming capacity issues and labour constraints. But how do you ensure a favourable outcome? Here Craig Whitehouse, Managing Director of Invar Integration offers a seven-point checklist for design success.

- Understand future business goals

The future may be difficult to predict, but important questions on business direction need to be asked. Beyond short-term objectives, such as sales targets and planned promotional peaks, it’s essential to gain insights into the future strategic ambitions of the business.

Any level of investment in automation will be justified by its return on investment over a given period – the faster the better. But corporate goals can change, new opportunities may arise and this could impact product profiles, volumes and formats, along with customer service offerings. Gaining a full understanding of C-suite plans and objectives to a five-year horizon will be invaluable in determining the scope and scale of solution that may be required.

Big questions include: what financial resources are available for any automation project? Limited capital may not preclude automation, as point solutions and scalable technology can be deployed in stages over time. What are the constraints on the warehouse – long or short lease, physical layout, ability to expand? What level of growth is the business expecting year-on-year – is it 20% or more? These are prime considerations for shaping any solution.

Above all else, be clear in setting objectives. What problems are you trying to solve?

- Examine your pain points

Automation may be adopted for any number of reasons, such as: increasing capacity, reducing reliance on labour, overcoming space constraints, lowering costs, increasing storage density, speeding processes, introducing higher levels of accuracy or enhancing operational resilience. But where in the warehouse can technology be best applied in order to deliver the desired objectives?

It’s important to determine where the bottlenecks and pain points are within current warehouse processes and hence where technology would bring the greatest gains. The answers are not always obvious or may not be as obvious as they sometimes look. Relieving a pressure point may introduce problems elsewhere, so a holistic approach is needed, backed-up by comprehensive data analysis.

- Analyse the data

Careful analysis of operational data lies at the heart of the design process and is critical to reaching the best solution. It’s essential to understand the performance of each process. Information relating to order profiles, order volumes, throughput rates, labour costs, volumetrics etc., provides the basis for determining the shape of possible solutions. But it’s a task that requires specialist skills, clever tools and expert advice.

Analysis can be undertaken in a number of different ways. An Excel spreadsheet may be used to generate a broad profile, so a complete set of stock data and orders could reveal what products would make sense to group together in an automated system and what products may, say, be too large, needing a different handling solution. Of course, automation may not always be appropriate – perhaps volumes are not high enough or the product profile is more suited to a manual process.

Experience and expertise pays dividends, as there is always a danger of creating unnecessary complexity. For instance, producing hundreds of different product categories can introduce confusion, resulting in rigid processes and cumbersome, inflexible systems. Similarly, there can be a temptation to use technology where it’s not necessary or an overly sophisticated solution could be overkill.

- Review appropriate technologies

There are many different technologies that could, potentially, be used – from Autonomous Mobile Robots (AMRs), zone-routing conveyors and flow-racking to cross-belt sorters, pick-to-light systems and automated packaging solutions, to name but a few. However, finding the most effective and appropriate combination for the defined set of objectives requires technical knowledge, creative thinking and access to advanced tools.

Importantly, it helps if you consult an independent systems integrator as, not being bound by any one technology or in-house manufactured solution, they are free to be objective about specifying the right solution for the application. Bringing a combination of technologies together in a cohesive way, based on process efficiency and overall performance, is what counts and much of this depends on the software development and the skills of the integrator to successfully tailor the solution for optimum performance.

- Model the outcomes / scenarios

Once it has been decided that some form of automation is needed, the next step is to review appropriate technology and model the solution to see how it performs.

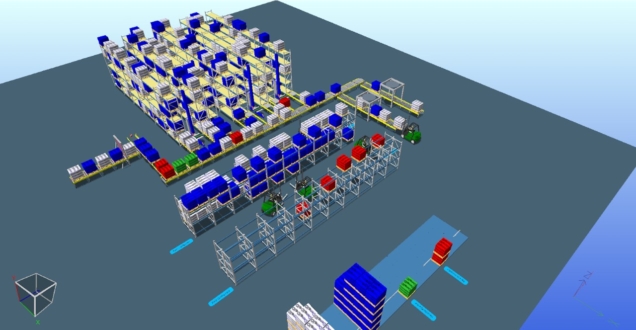

Simulation software brings a concept to life. At Invar Group, we have invested in leading-edge 3D simulation technology that enables us to select the most suitable materials handling hardware from a virtual catalogue and place appropriate technologies together as a concept system within the software. Then, by inputting a customer’s real data set, we can apply routing logic to allow us to view its performance and see in advance, any potential bottlenecks in the system.

Testing a concept in this way highlights where in the system there is too much capacity and where there isn’t enough, and hence, where expansion is required. Then you can scenario plan for what ifs, such as twice as many orders, or twice as many products, what if slow movers became fast movers and what happens at peak?

- Design in flexibility and scalability

Most investments in automation are aimed at increasing capacity to facilitate growth. That’s why designing a system for flexibility and scalability is so important. Using the right technology, a point solution can be expanded to grow with the business – that’s a benefit of modular technology. In recent years, tremendous advances have been made in areas such as mobile robotics and AI, giving SME’s access to low-CapEx solutions with huge benefits.

Autonomous Mobile Robots (AMRs) offer tremendous flexibility and, importantly, scalability in traditional labour-intensive tasks such as order picking and put-away. AMR systems combined with pick-to-light technology can boost order picking performance from under 100 units per hour using traditional methods, to up to 400 picks per hour, with an ROI that can be as little as 12 months.

Mobile robots may also be used effectively to transport pallets within a warehouse, offering a more flexible alternative to fixed pallet conveyors.

Flexible technology combined with powerful, intelligent software allows for a new way of thinking. A conventional conveyor system is normally installed to an agreed throughput, usually to a projected peak figure. But this results in the asset running below capacity for the majority of the year. On the quietest day it may only handle a tenth of the volume experienced at peak. However, a solution using AMRs could be designed for 70% of peak, with additional robots brought in during peak periods. It’s this level of scalability that offers SMEs a flexible low-entry point to automation.

- Select an experienced partner

There may be any number of processes within a warehouse that are found to be a constraint on optimum performance and there are many well-proven technologies that can be deployed – from weighing and auto volumetric sizing of goods received, conveyor runs and ASRS systems, to automated packaging machines, sortation equipment and pick-to-light technology, to name but a few.

Importantly, it is the efficient integration of these processes, technologies and intelligent software that enables fast delivery of a solution and a trouble-free future. An intelligent system, conceived by expert design engineers and implemented by competent controls and software professionals, drives productivity and offers the agility needed to respond to change.

As an independent, full-spectrum automated warehouse solutions provider, Invar Group is free to select the most appropriate technology for the task, and being a multifaceted organisation that brings together skilled individuals with competencies across warehouse management software, systems integration and controls, we take responsibility for the complete turnkey-key system from start to finish.