-

ROSSLARE EUROPORT TARGETS HEALTH & SAFETY WITH CAMERA TELEMATICS PARTNERSHIP - 2 days ago

-

Landmark Study Reveals Wearable Robotics Significantly Boost Safety and Efficiency in Industrial Environments - July 24, 2024

-

Visku Tackle The Retail Seasonality Challenge One Pallet At A Time - July 22, 2024

-

KAMMAC AND BERGEN LOGISTICS STRENGTHEN FASHION & LIFESTYLE SERVICES IN THE UK - July 19, 2024

-

TENTBOX EXTENDS PARTNERSHIP WITH ARROWXL TO SUPPORT INCREASING DEMAND - July 17, 2024

-

The Perfume Shop improves customer journeys while driving profitability in partnership with Scurri - July 17, 2024

-

ZEROMISSION SECURES £2.3M ($3M) INVESTMENT TO ACCELERATE ELECTRIC FLEETS - July 16, 2024

-

BCMPA CELEBRATES SUCCESS OF 2024 CONFERENCE - July 15, 2024

-

Best of the Best: Jungheinrich Celebrates Triple International Award Win - July 12, 2024

-

GOPLASTICPALLETS.COM CALLS ON NEW CHANCELLOR RACHEL REEVES TO CONSIDER PLASTIC PACKAGING TAX REFORM - July 10, 2024

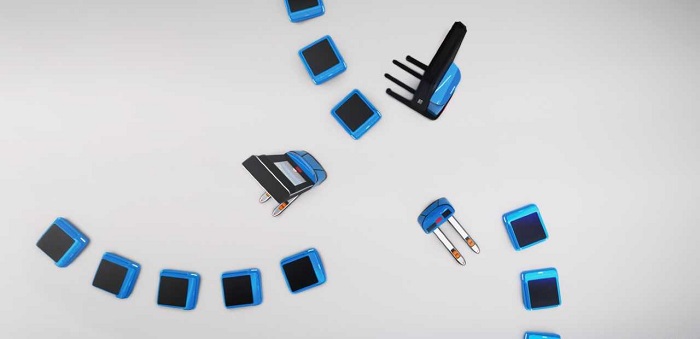

Toyota’s ‘A.I.TeamLogistics’ concept presented at CeMAT 2018.

Toyota Material Handling Europe will again be taking a look to the future at this year’s CeMAT exhibition, which forms part of Hannover Messe. One of the latest concepts developed by the company is presented in a film animation and also a virtual reality environment. The ‘A.I.TeamLogistics’ concept suggests how extreme optimisation of handling processes might look during the next decade.

Toyota’s ‘future technology’ presentation at the 2016 CeMAT exhibition attracted serious attention from visitors, including the ‘pallet drone’ and ‘swarm’ concepts – both hinting at the shape of future horizontal transport.

This year Toyota takes this thinking to a higher level, envisaging the way that horizontal transporters might communicate directly with high-level machines using artificial intelligence.

The idea is that all movement should be optimised, with exactly the right type of handling machines being deployed for each task, passing loads between machines as required.

‘Artificial intelligence based on millions of calculations every second will allow trucks to identify the optimum route and use of resource,’ explains Boris Ahnberg, a key member of Toyota’s R&D team, who has been leading the project. “By using this type of direct communication it means that traditional central warehouse management system control will no longer be required – it will just be a matter of machine-teamwork.’

The concept directly reflects Toyota’s lean approach to logistics operation, based on the respected Toyota Production System. A key principle of lean-thinking is the elimination of waste, and extreme optimisation of resources contributes to that goal.

Alongside the A.I.Teamlogistics story, Toyota is also presenting the next stage of development for the Swarm concept, with a unit in operation on the CeMAT booth. Using traditional WMS control Swarm units are already being developed to work in collaboration with Vanderlande baggage handling systems. The concept of the ‘Pallet Drone’ is showcased at the Microsoft stand in Hall 7 at Hannover Messe.

The CeMAT is taking place between 23 and 27 April at the Hannover fairground, Germany. Toyota Material Handling Europe will exhibit at its normal high-profile location at pavilion P32. For further information please visit: www.cemat-toyota.eu.